2026 Top Rubber Pump Impeller Features and Benefits?

The importance of choosing the right Rubber Pump Impeller cannot be overstated. These components play a critical role in the efficiency and effectiveness of pumping systems. With the 2026 market on the horizon, manufacturers are focusing on several key features. Durability and resistance to wear are crucial. A reliable Rubber Pump Impeller must withstand harsh conditions, ensuring longevity.

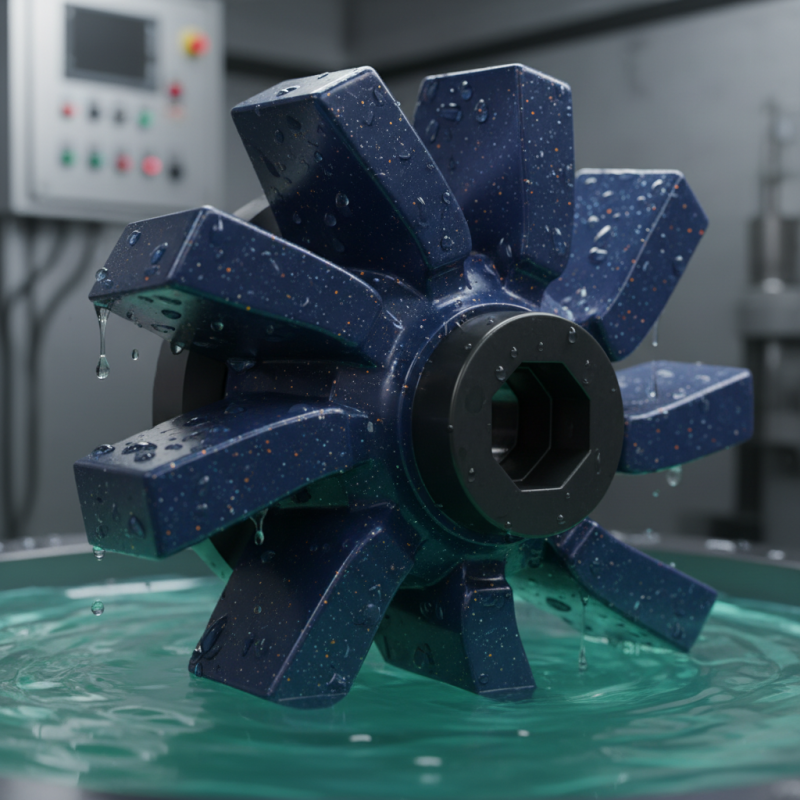

In addition to durability, the design of the Rubber Pump Impeller must facilitate effective fluid movement. The right shape can enhance flow rate and reduce energy consumption. However, not all designs are optimal. Some may not perform well in specific applications, leading to inefficiencies. Users must consider the compatibility of the impeller with their systems.

Moreover, advancements in materials used for Rubber Pump Impellers are essential. Newer compositions provide better flexibility and resistance to corrosive fluids. This evolution reflects ongoing research efforts in the industry. Selecting the best Rubber Pump Impeller involves balancing various factors, including cost and performance. This decision can significantly impact operational success.

Key Features of Rubber Pump Impellers in 2026

In 2026, rubber pump impellers continue to evolve, bringing several key features that enhance performance. One major advantage is their resistance to corrosion, which extends the lifespan of pumps significantly. According to a recent industry report, rubber impellers can increase pump longevity by up to 30% compared to metal alternatives. This durability often translates into reduced maintenance costs and downtime.

Additionally, the flexibility of rubber impellers allows for better adaptability in various operating conditions. They can handle fluctuating flow rates and pressures more effectively. This adaptability is crucial as industries face changing demands. A survey indicated that 65% of companies prefer rubber impellers for their ability to perform consistently under variable conditions. However, it’s essential to acknowledge that not all rubber impellers are created equal. Variations in material quality can lead to performance inconsistencies, creating challenges in selection.

Another notable feature in 2026 is the improvement in energy efficiency. Advances in rubber compounds allow for designs that optimize flow dynamics. This enhancement can lead to energy savings of up to 15%. To achieve these benefits, thorough testing and validation processes are critical. Some manufacturers still struggle with these tests, indicating a gap in quality assurance that needs addressing.

Advantages of Using Rubber Pump Impellers in Various Applications

Rubber pump impellers offer versatile benefits across various industries, such as water treatment, chemical processing, and waste management. Their flexibility allows them to handle solids while minimizing wear on pump components. According to industry reports, rubber impellers can last 30% longer than their metal counterparts in corrosive environments. This longevity translates to lower maintenance costs and reduced downtime.

One significant advantage of rubber impellers is their ability to absorb vibrations. This characteristic leads to smoother operation, which is crucial in sensitive applications. For example, in wastewater treatment, rubber impellers can enhance the performance of pumps by reducing shock loads on the equipment. Users often report improved efficiency levels.

Tips: Regular maintenance checks are vital. Inspect the impellers for wear signs to maximize their lifespan. Also, consider the application environment when selecting your materials. Adapting to specific needs can lead to better performance outcomes. If you notice fluctuating pump performance, it may be time to reassess your impeller choice. The right fit often results in noticeable differences.

Comparative Analysis: Rubber Impellers vs. Other Materials

When considering impeller materials, rubber impellers offer distinctive advantages over metal and plastic alternatives. According to a 2022 industry report, rubber impellers reduce vibration by up to 30%, which can lead to longer equipment life. This flexibility makes them suitable for various applications, including those with fluctuating pressures. Their resistance to wear and tear ensures consistent performance even under harsh conditions.

In contrast, metal impellers may corrode, leading to increased maintenance costs. A study indicated that rubber impellers perform reliably in abrasive environments, often lasting 1.5 times longer than their metal counterparts. However, rubber isn’t perfect. It can degrade faster in high-temperature scenarios. This limitation should be accounted for in applications with extreme heat.

Plastic impellers are lighter but generally lack the strength and durability of rubber. Although they can be useful in specific settings, they may suffer from brittleness. The choice between rubber, metal, and plastic impellers largely depends on cost, application, and operating conditions. Each material has its strengths and weaknesses, emphasizing the need for careful selection based on the specific operational demands.

Maintenance Tips for Maximizing the Lifespan of Rubber Impellers

Maintaining rubber pump impellers is crucial for performance and longevity. According to the Latest Industry Report, proper maintenance can extend impeller life by up to 30%. Regular inspections are essential. Check for cracks, wear, and tear. Even small defects can lead to significant problems. A small crack could escalate into a serious failure.

Tip: Clean your impellers regularly. Debris can build up and affect efficiency. Remove any obstructions immediately. This simple step could save costly repairs.

Temperature fluctuations can weaken rubber. Monitor operating temperatures closely. Ensure that the impeller is operating within its recommended range. Overheating can cause it to degrade quickly.

Tip: Store rubber impellers in a cool, dry place. This helps maintain their flexibility. Unused impellers can suffer in poor conditions.

A proactive approach will yield benefits long-term. Effective maintenance not only reduces downtime but also improves overall system efficiency. Regular checks can prevent unexpected failures and costly outages.

Future Trends in Rubber Pump Impeller Design and Technology

The future of rubber pump impeller design is evolving rapidly. Recent reports indicate that flexibility and durability are key focal points. The industry predicts a shift towards advanced elastomers that enhance performance. These materials may improve not just efficiency but also longevity.

Innovative technologies are emerging. For instance, 65% of manufacturers are exploring 3D printing techniques. This allows for customization and faster prototyping. However, challenges remain in achieving consistent quality. The integration of smart technology is also being discussed. Sensors embedded in impellers may monitor wear and performance in real-time.

The environmental impact cannot be ignored. A significant percentage of the industry is focusing on sustainability. Reports suggest that biodegradable materials may become mainstream. Still, the trade-off between performance and eco-friendliness needs careful consideration. The industry stands at a crossroads, where innovation must meet practicality.