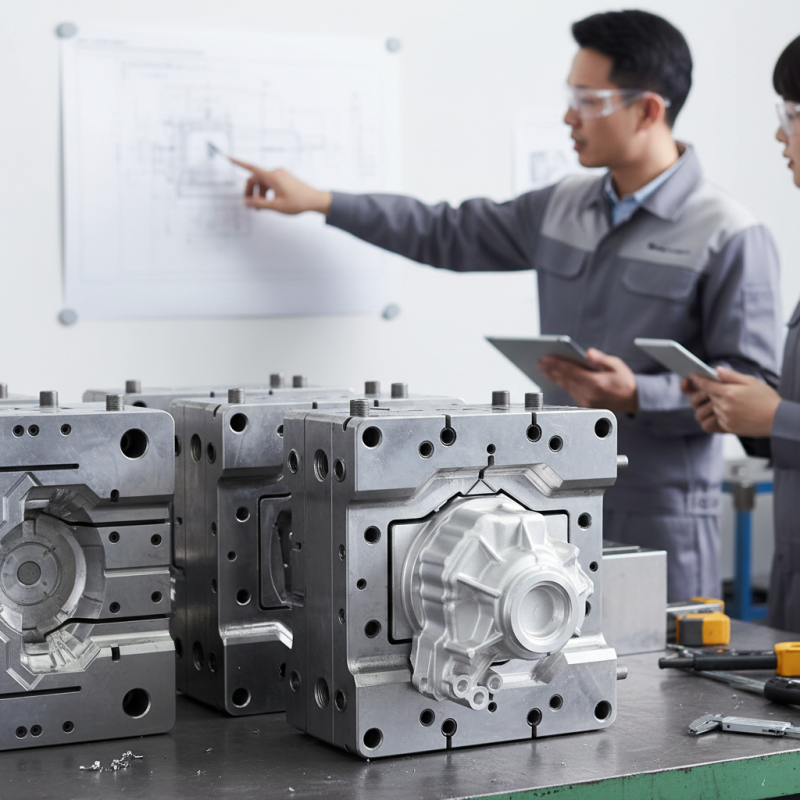

Essential Tips for Choosing Die Casting Molds?

When selecting Die Casting Molds, industry expert John Smith emphasizes the importance of precision. He once stated, "The right mold can make all the difference." This highlights how crucial it is to make informed decisions in the die casting process.

Die casting molds play a pivotal role in shaping the final product. Choosing the wrong mold can lead to defects and wastage. It's essential to consider material quality, design specifications, and production efficiency. Each of these elements significantly affects the outcome. The complexity of the design often poses challenges. Some molds may not perform as expected, leading to frustration.

In identifying the ideal die casting molds, manufacturers should embrace a detailed evaluation process. This involves analyzing every aspect, including durability and temperature resistance. Small details can easily be overlooked but can dramatically alter results. Reflecting on mistakes can pave the way for improved strategies. Investing time in this decision is crucial for success in die casting projects.

Understanding the Basics of Die Casting Molds

Die casting molds are vital in manufacturing. Understanding them is essential for efficiency. They allow for high precision and repeatability in production. According to a recent market report, the global die casting market is expected to reach $83.2 billion by 2027, growing at a CAGR of 5.6%. This shows the increasing importance of die casting in various industries.

Choosing the right mold can be challenging. Factors like material, design, and lifespan must be considered. Aluminum molds, for example, offer lower costs but may wear faster than steel molds. Steel molds last longer but are more expensive. A study revealed that nearly 30% of manufacturers report issues with mold quality, leading to inconsistent production. This highlights the need for careful selection.

In addition, considering the cooling time is critical. Inefficient cooling can lead to defects and increased cycle times. This impacts overall productivity. Seeking input from experienced engineers can prevent costly mistakes. A rigorous evaluation process can save time and resources, but many overlook this step. It’s essential to reflect on the balance between cost and quality.

Key Factors to Consider When Choosing Die Casting Molds

Choosing die casting molds can be a complex process. There are many factors to consider to ensure quality and efficiency. Material selection is crucial. Aluminum and zinc are popular choices, but have different characteristics. Each metal responds to heat and stress differently, impacting the final product.

Tip: Always evaluate your project’s requirements. Think about how your design influences mold choice. Small changes can lead to issues during production. A well-considered design saves time and money.

Another important factor is the mold design itself. The cooling channels play a significant role in the casting cycle. Efficient cooling leads to better surface finish and reduces cycle time. A great mold can make or break your casting process.

Tip: Communicate with your mold maker. Ask questions and seek advice. A good partnership can lead to better outcomes. Remember, refining your mold choice process takes time. Each project offers lessons learned. Take notes on what works and what doesn't. Be ready to adapt.

Essential Tips for Choosing Die Casting Molds

| Factor | Description | Importance |

| Material Selection | Choose the right metal alloy to ensure durability and performance. | High |

| Design Complexity | Consider how intricate the mold design is and its relation to production efficiency. | Medium |

| Cooling System | Evaluate the cooling capabilities of the mold to avoid defects. | High |

| Cost Effectiveness | Balance initial investment with long-term operational costs. | Medium |

| Lead Time | Consider the production timeline to meet market demands efficiently. | High |

| Manufacturer Expertise | Research the expertise and experience of the mold manufacturer. | High |

Different Types of Die Casting Molds and Their Applications

Choosing the right die casting molds is crucial for efficiency and product quality. Different types of molds exist, each catering to specific needs. For example, single cavity molds are ideal for small production runs. They reduce costs but may limit output. In contrast, multi-cavity molds can significantly increase production rates, making them popular for mass manufacturing.

Aluminum molds are commonly used due to their lightweight and heat conductivity. They are suitable for a variety of applications, including automotive parts and electronics. According to industry reports, the global die casting market size is projected to reach $18.9 billion by 2027, driven by increasing demand in various sectors.

When choosing a mold, consider the cooling rate. A good cooling mechanism can decrease cycle time and improve efficiency. Also, inspect mold materials. High-quality materials lead to better longevity, reducing maintenance costs. Lastly, reflect on the design complexity. Simple designs are more cost-effective but may not be suitable for intricate features.

Material Selection for Die Casting Molds: What to Know

Material selection is crucial for die casting molds. It impacts production quality, cost, and lifespan. Common materials include steel and aluminum. Steel is durable but costly. Aluminum offers lightweight but shorter life expectancy. According to a recent industry report, high-carbon steel molds last 20% longer than aluminum molds. This can lead to a significant reduction in production downtime.

The choice also hinges on the complexity of the parts. Intricate designs may require more sophisticated materials. For example, tool steels with high resistance to wear are advisable. They may seem expensive upfront but prove economical over time. Industry studies indicate that high-performance materials can reduce mold wear by as much as 30%. However, these materials are not always easy to machine, leading to potential challenges in production.

In addition, the environment of the casting process should not be overlooked. Factors like temperature and pressure influence material performance. Some materials may degrade under high-stress conditions. Evaluating material properties against production needs can be tricky. Many companies still struggle to find the right balance between cost and performance. Investing time in material analysis pays off, but many overlook this critical step.

Best Practices for Maintaining Die Casting Molds

Choosing the right die casting molds is just the beginning. Proper maintenance is crucial for long-lasting performance. Regular cleaning is essential. Remove any residue after each use. This helps prevent buildup that can affect future castings.

Inspect your molds frequently. Look for signs of wear or damage. Small cracks can grow over time if unnoticed. Address these issues promptly to avoid costly delays. Lubricating moving parts regularly can enhance functionality. This minimizes friction and prolongs mold life.

Recordkeeping is often overlooked. Maintain logs of maintenance activities. Documenting this can help identify patterns in wear. If an issue arises, you’ll know the last service performed. Relying on memory can lead to negligence. Keep your molds in a controlled environment. Temperature fluctuations can cause warping over time.