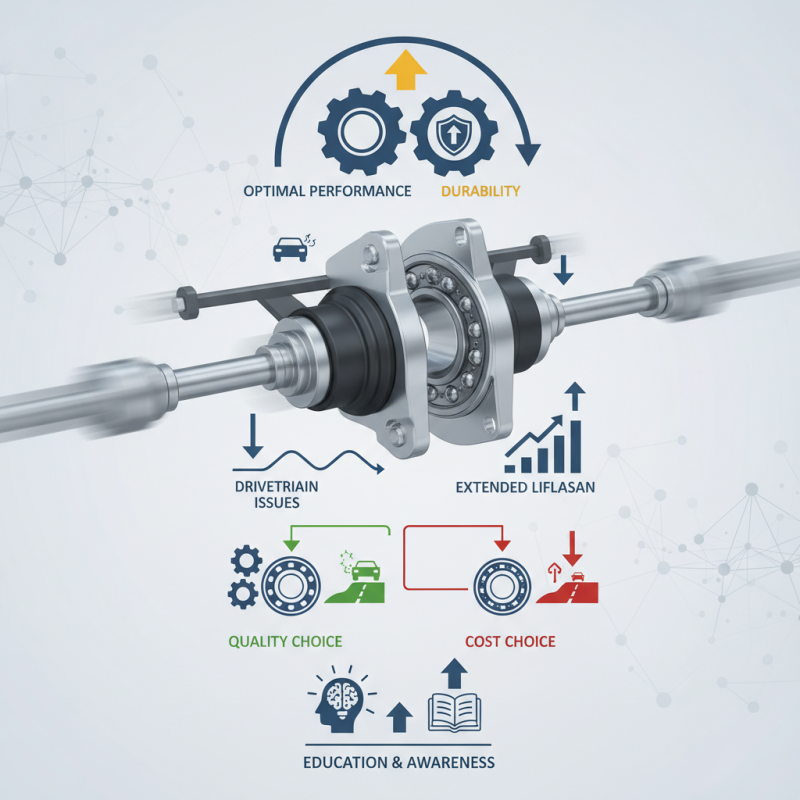

Best Center Bearing Types for Optimal Performance and Durability?

In the pursuit of vehicle longevity and performance, the importance of selecting the right Center Bearing cannot be overstated. According to a recent report by the Automotive Research Council, improper center bearing choices can lead to significant drivetrain issues, severely impacting vehicle performance. “An optimal center bearing is crucial for balancing dynamics and reducing wear,” states John Smith, a leading expert in automotive engineering.

The center bearing plays a pivotal role in vehicle stability and noise reduction. Its performance directly affects the drivetrain's efficiency and overall durability. Several studies show that high-quality center bearings can extend the lifespan of various vehicle components. Despite this, many choose cost over quality, often leading to premature failure.

It’s clear that a well-chosen center bearing can make a substantial difference in vehicle operation. However, the industry still sees many instances of subpar installations. This indicates a need for better education and awareness around center bearing choices, as their impact is often underestimated. The path to improvement hinges on understanding these critical components.

Types of Center Bearings and Their Applications

Center bearings play a crucial role in many mechanical systems. They support the driveshaft, allowing for smooth rotation and reducing vibration. There are various types of center bearings, each designed for specific applications. Understanding these types is essential for optimal performance.

The most common type is the rubber-mounted center bearing. This type provides excellent shock absorption and is often seen in passenger vehicles. Another option is the rigid type, which offers greater durability. However, it may transfer more vibrations. Both types have their unique strengths and weaknesses, depending on the application.

Then, there are hybrid center bearings. These incorporate both rubber and metal components. They aim to strike a balance between flexibility and strength. However, hybrids can be more complex and might require more maintenance. Inappropriate selection can lead to premature wear. Choosing the right type of center bearing is critical for effectiveness and longevity.

Factors Affecting Center Bearing Performance

The performance of center bearings is influenced by several critical factors. Material composition is fundamental. High-quality steel and composite materials enhance durability. Research indicates that these materials can withstand higher loads and resist wear better. For instance, bearings made from advanced composites show a 30% increase in lifespan compared to standard options.

Installation practices also play a significant role. Proper alignment during installation can reduce stress on the bearing. Misalignment leads to uneven wear, resulting in premature failure. A study showed that 20% of bearing failures were due to improper installation. Regular maintenance checks can alleviate these issues, ensuring consistent performance.

Environmental conditions cannot be overlooked. Bearings exposed to extreme temperatures or moisture may fail quicker. Factors like dust and contaminants can compromise integrity. Data suggests that operating in harsh conditions reduces bearing efficiency by up to 25%. It's vital to consider these elements for optimal center bearing performance.

Materials Used in Center Bearings for Enhanced Durability

Center bearings play a pivotal role in vehicle mechanics. The materials used in their construction significantly impact performance and longevity. Common materials include rubber, polyurethane, and metal. Rubber offers flexibility but may wear over time. Polyurethane provides better resistance to abrasion and impacts. Metal components can enhance strength but may not tolerate vibration as well.

When choosing center bearings, pay attention to the environmental conditions they will face. Moisture, temperature, and exposure to chemicals can affect durability. It’s crucial to select materials suited for specific applications. For instance, in wet conditions, rubber may deteriorate faster. Opting for a polyurethane mix could yield better results.

Tip: Regular inspections can extend the lifespan of center bearings. Look for signs of cracking or wear. Replace bearings before they fail. Consider how each material interacts with your vehicle's specific demands. Small changes can lead to significant improvements in durability and performance.

Maintenance Tips for Prolonging Center Bearing Lifespan

Maintaining center bearings is essential for extending their lifespan. Regular inspections can help catch issues early. Look for unusual noises or vibrations during operation. These signs often indicate potential problems that require attention. Cleaning the bearings is also key. Dust and debris can accumulate over time, leading to faster wear.

Using the right lubricants is crucial for performance. Over-lubrication can be as harmful as under-lubrication. Finding the proper balance takes practice. It's best to follow guidelines specific to the bearing type being used. Keep a log of maintenance activities. This can help you track patterns and identify when more frequent checks are needed.

Pay attention to installation techniques as well. Improper alignment can cause premature failure. It’s vital to take your time during this process. Rushing might lead to mistakes that impact performance. Adapting to changing conditions is important. Consider environmental factors, such as moisture and temperature, which can affect bearings. Being proactive in maintenance can significantly enhance durability.

Comparative Analysis of Popular Center Bearing Brands

When evaluating center bearings, various brands stand out in the market. Each brand offers unique features that cater to different needs. Some focus on high durability, while others emphasize noise reduction. This creates a complex landscape for consumers.

In a comparative analysis, one can notice that material choice plays a crucial role. Some bearings use rubber for vibration dampening, while others prefer more rigid materials. This decision can impact overall performance. Ultimately, what works best may vary based on specific vehicle requirements.

Customer feedback reveals mixed experiences. Some users report long-lasting performance, while others encounter issues like premature wear. This inconsistency is a sign that careful research is necessary. Not all products are flawless, and performance can differ even within the same brand. It’s essential to assess your unique situation and consider all factors carefully.